How To Make Plastic From Hemp

Hemp Plastic is the Future

Plastic has become a pressing topic recently both in the UK and across the world. Mainly because it’s killing the vast majority of nature and will doom us all. So for this reason, a lot of people are looking for effective alternatives to petrochemical-derived plastics. One material that is showing a huge amount of promise is hemp.

Hemp has been cultivated for a variety of uses for millennia. For as far back as Ancient China, from food to fabric, hemp has found a place in nearly every niche imaginable. One under-explored use of hemp is that it can be used to make plastics.

There are many initiatives being tabled to combat the proliferation of plastic waste in the environment. These include recycling and stricter regulations, and while these methods help, the most effective way to combat plastic contamination is to reduce the amount of petrochemical plastic we use in manufacturing. After out of the ‘Three Rs’; reduce, reuse, and recycle, reduction has proven to be the most effective.

Reducing Our Reliance On Petrochemicals

Reducing industry’s reliance on petrochemicals has been a major environmental objective for the last decade. A lot of progress has been made with the use of renewable energy and more efficient supply lines, but the vast majority of our products are still made of petrochemical plastics. This is mainly down to the fact that plastic is a cheap and versatile material.

Hemp cellulose has shown properties that make it an ideal raw material for plastic. it can be made into cellophane for food packaging, rayon for cleaning products, and celluloid for a whole range of consumer products.

How Does Hemp Plastic Biodegrade?

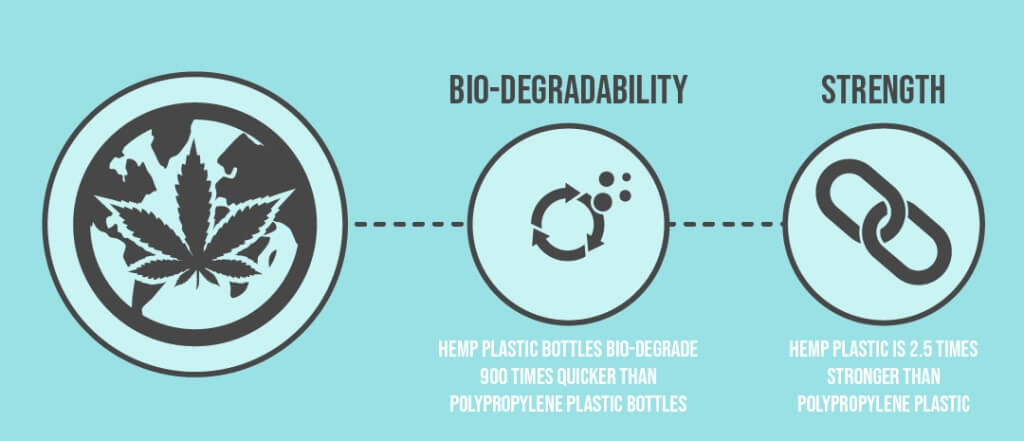

Hemp plants contain as much as 70% cellulose, so a single harvest could produce a huge amount of raw material. As a crop, hemp is incredibly easy to grow with a relatively small carbon footprint. It doesn’t require any artificial pesticides or fertilizers, and it grows far faster than comparable crops such as cotton.

Hemp is already in use in composite bio-plastics that are used widely due to their high strength, rigidity, and lightness.

Can Hemp Plastic become mainstream?

The majority of plastics we encounter in our day to day life in a form known as polymer resin, while hemp plastics show a lot of promise, they don’t have the versatile properties of this resin. In time the technology may catch up and allow us to produce hemp plastics that can take on every role of traditional plastics.

Another obstacle for hemp plastic is the cost associated with producing it. At the moment petrochemical plastics can be produced on a huge scale cheaply. This is mainly down to the decades of refinement that have been put into its manufacturing process. Hemp plastics is still relatively new, the most efficient means of producing it have yet to be developed.

Finally, hemp is a member of the cannabis family; a drug that is under prohibition in much of the world. Though it contains practically none of the psychoactive ingredients that are found in cannabis, hemp faces the same level of legal stigma. Its hard to research a plant that you’re not legally allowed to possess or grow.

Conclusion

Hemp plastic could well be the way of the future in the UK, but cost, technology, and legal status have all proven to be obstacles. These may seem like daunting problems, but cannabis is undergoing sweeping legalization in many western countries, and once it’s legal, research could make sure that the other two factors will be overcome in no time.