Hemp Clothing: How It’s Made

What do George Washington, James Madison, Thomas Jefferson, and Andrew Jackson have in common? Yes, they were all well-known early US presidents, but more importantly for us, they all farmed hemp! They shared this occupation with the pilgrim fathers, European farmers from the middle ages onwards, the ancient Chinese, and pretty much every past society that wore clothes.

-

CBD Products, CBD Vape, CBD Vape, Disposable Vape Pens, Vaping Products

Darwin The Big One 2000mg CBD Disposable Vape Device 3000 Puffs

£19.00

Why Hemp?

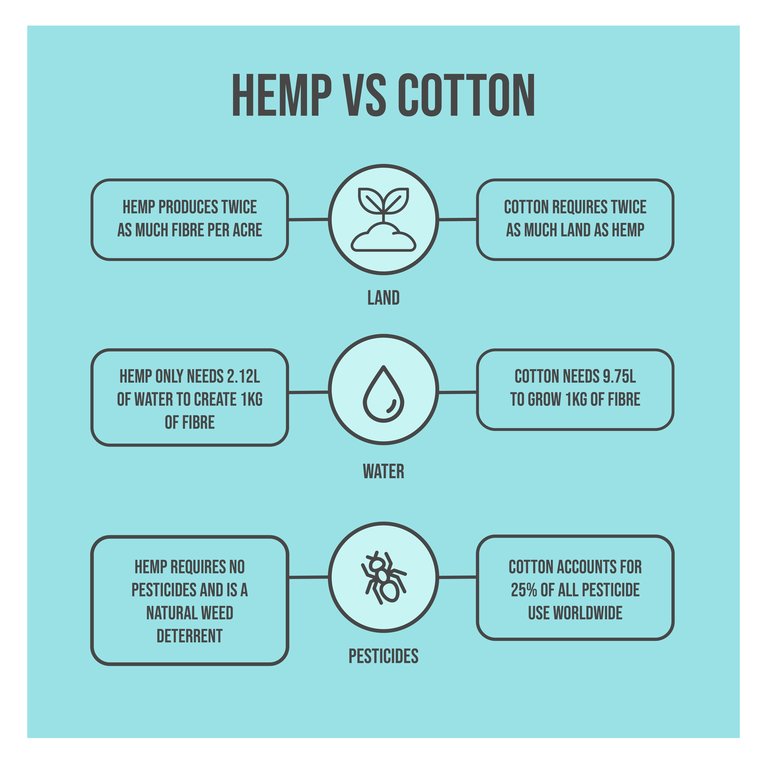

Artificial fibres have given us plenty of cheap, durable clothing, but we know that we need to find alternatives to these plastics and keep oil in the ground. Our overuse of agricultural chemicals is leading to the mass death of wildlife worldwide, and even of some farmers in cotton-growing countries like India. Soil erosion and compaction are leading to reduced harvests everywhere, with the UN estimating that there are only 60 years of harvests left before world food production collapses.

Hemp is a durable, comfortable, and rot-resistant natural fibre that easily grown. It needs no pesticides or fertilisers, and it stabilises and aerates the soil. These eco-friendly features mean that this ancient plant is a future-proof farm product.

So How It Done?

Hemp is still made into clothing in pretty much the same way as it was done in George Washington day, when he farmed hemp. It got to be harvested, wet, dried, separated, sorted, spun, and woven. We use more machines in the process these days, but these basic steps havent changed.

Cutting and Retting

First, the plant must be cut or pulled out of the ground. It then retted – submerged in a stream or pond for a few days. If no water source is nearby, retting can be done by leaving it in the field for a couple of weeks so the morning dew does the job. This separates the fibre on the outside from the woody stem core in the middle.

Scutching and Hackling

The hemp stems are rolled between heavy rollers, or crushed in some other way. This is called scutching. That breaks apart the woody cores to further separate the fibre from them. Hackling is then when the fibres are pulled through a big metal comb, to straighten them out, and remove debris. In the past, professional hacklers were often known for being aggressive and boisterous, eventually morphing into the modern name for heckling in performance arts.

Spinning and Weaving

The smooth, separate fibres are then spun together into string and thread. Then, they can be woven like any other fibre into sheets to be manufactured into long-lasting, tough, comfortable, and sustainable clothes of all shapes and sizes!